S160 Gas Chamber Gas System Manual

Contents

-

Overview

-

Check points

-

Procedure to

add methylal

Overview

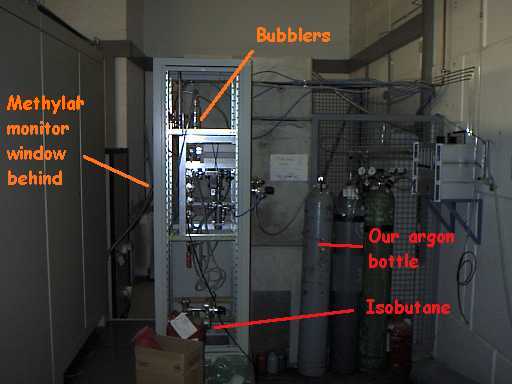

The following picture shows the overview of the S160 gas system.

It is located at the far end of the magnet power supply gallery.

Familiarize yourself with the locations of our argon bottle, isobutane

bottle, bubblers and methylar monitor window.

Check points

-

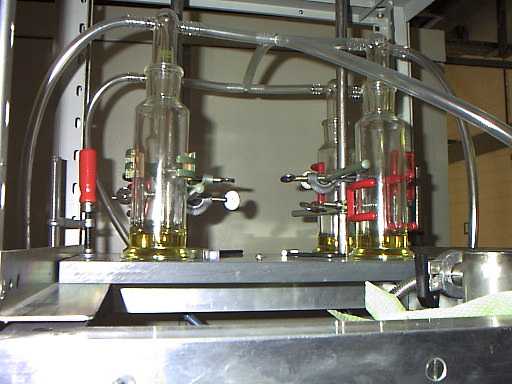

Look at the bubblers. Bubbles should be coming out of all four bubblers

at a rate of about one per second.

-

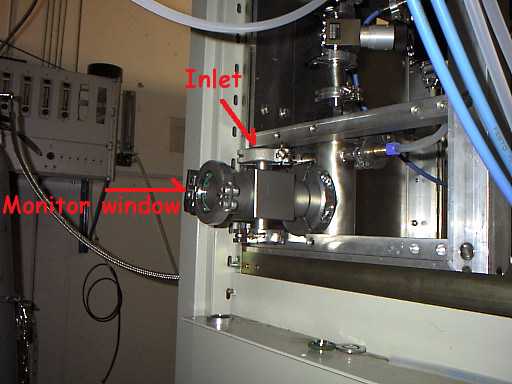

With a flash lamp, look into the methylal monitor window. The methylal

liquid surface should be visible through this view port. If not,

follow the methylal

filling procedure described below.

-

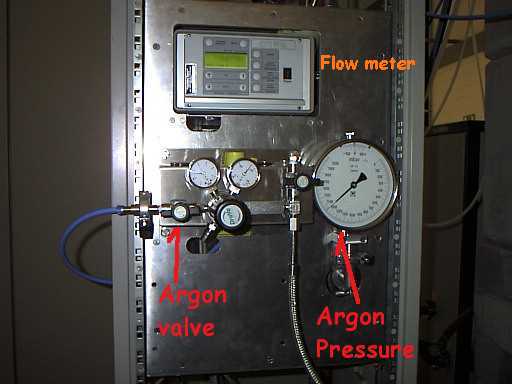

Look at the gas flow meter. Two numbers are shown. The top

number is the argon flow while the bottom number is the isobutane flow.

What is important is the ratio of these numbers, i.e., isobutane/argon

~ .66. Normally this number should not change. If

this number is significantly different, we suspect that the isobutane bottle

is running low.

The procedure to add methylal.

When the methylal level is found low, the following steps must be followed

to add methylal.

-

Beam off, and turn off chamber HV.

-

Close the argon valve shown in the picture above.

-

Wait till the argon pressure is lowered to about 1000 mb (and the bubblers

stop bubbling).

-

Take out the methylal inlet flange, use a plastic funnel to pour in methylal.

-

Put on the flange.

-

Open the argon valve, wait for bubblers start bubbling.

-

Turn on chamber HV.